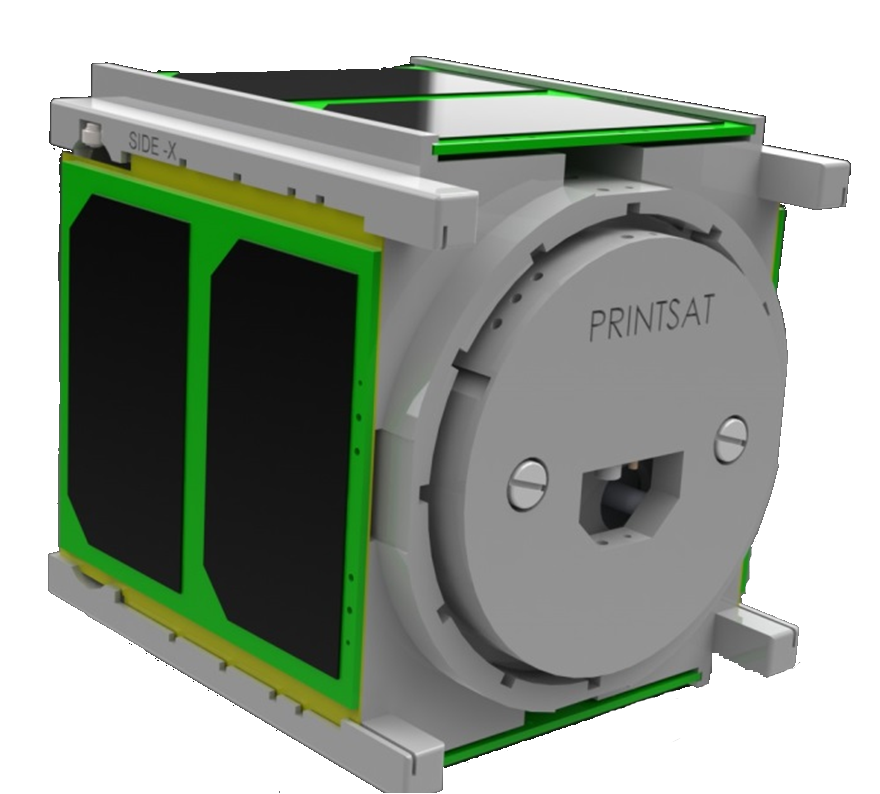

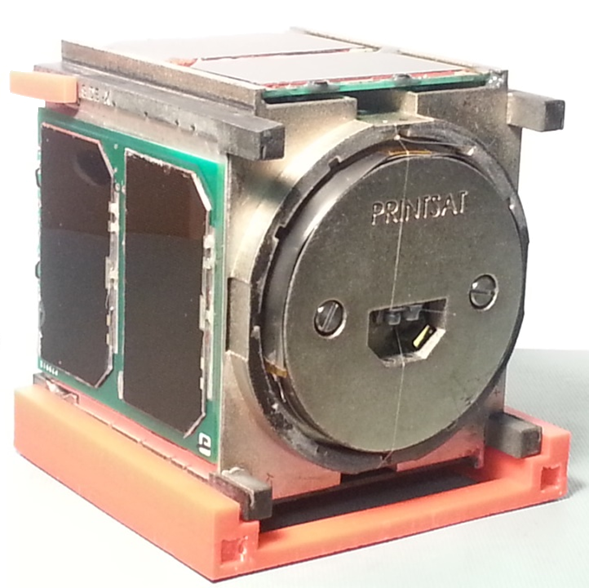

PrintSat

Mission Overview

The PrintSat mission was a technology demonstration to access the effectiveness of additive manufacturing (i.e. 3D printing) and the Windform XT material for use as a material for space structures.

The primary objectives of the PrintSat mission were:

- Demonstrate the use of additive manufacturing for primary and secondary structural elements for spacecraft

- Acquire measurements from several on-board sensors to quantify changes in the material properties through out the mission lifetime

- Develop insight into using additive manufacturing in a rapid build and production environment for space missions.

Spacecraft Overview

PrintSat was a 1U CubeSat weighing less than 1 kg. It carried several on-board sensors to help assess changes in the properties of the Windform material caused by exposure to the space environment. These sensors included a torsional strain gauge, surface resistivity monitor, and radiation microdosimeter

Status

PrintSat was lost in a launch failure of the experimental Super Strypi launch vehicle on November 3, 2015. The U.S. Air Force issued the following statement:

"The ORS-4 mission on an experimental Super Strypi launch vehicle failed in mid-flight shortly after liftoff at 5:45 p.m. Hawaii Standard Time (7:45 p.m. PST; 10:45 p.m. EST) today from the Pacific Missile Range Facility off Barking Sands, Kauai, Hawaii. Additional information will be released as it becomes available."

As of 2020, there are no plans to attempt another flight of PrintSat. The technology used for the spacecraft remains of interest to SSEL and continues to be used in non-structural components.

Image of the flight-ready PrintSat spacecraft